Northisle Extends Strike of Mineralization at West Goodspeed to 1km

Highlights:

- GS24-15 was drilled to target the area 200m to the west of GS24-10 and has intercepted 20m grading 0.87% Cu Eq., 38m grading 0.29% Cu Eq., and 54m grading 0.42% Cu Eq.

- GS24-11 through GS24-13 were targeted 350 metres down dip at West Goodspeed and, as expected, have intercepted narrower intercepts of copper and gold mineralization

- GS24-13 intercepted mineralization above the interpreted fault planes bounding known mineralization at West Goodspeed indicating a fault offset target for future exploration

- Remaining results from 2024 drilling include approximately 10 holes totalling 2,700 meters drilled at Northwest Expo and GS24-16, which is testing a further step out to the NW of GS24-15

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20241028558695/en/

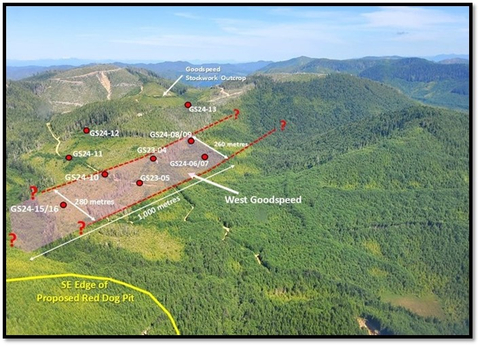

Figure 1: Aerial View Looking East to West Goodspeed (Graphic: Business Wire)

Recent assays for GS24-15 confirm the presence of copper and gold mineralization over three intercepts in this hole collared approximately 210m northwest of GS24-10, extending mineralization at West Goodspeed over a strike of at least 1,000m from northwest to southeast. As a result of the positive results in GS24-15, Northisle recently drilled GS24-16 to test a further step out northwest at the West Goodspeed deposit, to test the area between West Goodspeed and Red Dog. GS24-16 intercepted intense quartz-magnetite, quartz-amphibole-biotite and quartz-chlorite-magnetite vein stockworks and parallel vein arrays hosting chalcopyrite-bornite mineralization. Assays from this hole are anticipated in Q4 2024.

Significant intervals from 2024 drilling at West Goodspeed are shown in Table 1. GS24-11 through GS24-15 are the new holes released today.

Table 1: West Goodspeed Newly Released Significant Intercepts

|

Hole ID |

From

|

To

|

Interval

|

Cu Grade

|

|

|

|

Re Grade

|

Cu Eq.

|

Au Eq. Grade (g/t) |

|

GS24-11 |

185.0 |

210.0 |

25.0 |

0.12 |

0.016 |

0.003 |

0.53 |

0.298 |

0.17% |

0.25 |

|

GS24-12 |

301.0 |

320.4 |

19.4 |

0.13 |

0.095 |

0.005 |

0.74 |

0.353 |

0.23% |

0.33 |

|

GS24-13 |

254.0 |

305.0 |

51.0 |

0.17 |

0.181 |

0.04 |

0.004 |

0.172 |

0.32% |

0.46 |

|

GS24-15 |

24.0 |

44.0 |

20.0 |

0.37 |

0.194 |

0.057 |

0.33 |

3.539 |

0.87% |

1.26 |

|

and |

66.0 |

104.0 |

38.0 |

0.18 |

0.105 |

0.006 |

0.66 |

0.460 |

0.29% |

0.42 |

|

and |

171.0 |

225.0 |

54.0 |

0.22 |

0.155 |

0.013 |

0.54 |

1.062 |

0.42% |

0.60 |

|

GS24-16 |

Pending |

|

|

|

|

|

|

|

|

|

Copper and gold equivalent calculations based on the following metal prices which were used in the Company’s 2024 Integrated Resource Estimate for

Cu =

Note on equivalent calculation:

Copper equivalent is determined by calculating total contained metal value per tonne, dividing by the copper price, and then dividing the resultant number of pounds of copper by 2204.6. Gold equivalent is determined by calculating total contained metal value/tonne, dividing by the gold price, and then multiplying the resultant number of troy ounces of gold by 31.103. Analyzed metal equivalent calculations are reported for illustrative purposes only and assume 100% recoveries as metallurgical testing has not yet been completed on material from the West Goodspeed target.

West Goodspeed Drill Result Details

Assay results have now been received for nine of the ten drill holes completed during 2024 on the West Goodspeed target. These include GS24-06 (previously reported) to GS24-13 and GS24-15. GS24-14 was drilled to test a geophysical target located approximately 1km to the southwest of West Goodspeed. It intersected a series of volcanic rocks that had undergone extensive propylitic alteration, which may reflect the distal porphyry alteration footprint at West Goodspeed. GS24-14 is not anticipated to contain significant mineralization. All but two of the 2024 drill holes were oriented, and drilled from existing or reactivated forest service roads.

Table 2 shows the complete drilling data from 2024 exploration at West Goodspeed.

Table 2: West Goodspeed Significant 2024 Intercepts

|

Hole ID |

From

|

To (m) |

Interval

|

Cu Grade

|

|

|

|

Re Grade

|

Cu Eq.

|

Au Eq.

|

|

GS24-06 |

9.4 |

93.0 |

83.6 |

0.20 |

0.184 |

0.005 |

1.18 |

0.271 |

0.38% |

0.511 |

|

including |

9.4 |

69.2 |

59.8 |

0.22 |

0.201 |

0.005 |

1.24 |

0.291 |

0.42% |

0.556 |

|

and |

125.0 |

237.0 |

112.0 |

0.20 |

0.270 |

0.009 |

0.21 |

0.700 |

0.47% |

0.623 |

|

Including |

133.0 |

201.0 |

68.0 |

0.28 |

0.384 |

0.009 |

0.28 |

0.743 |

0.63% |

0.846 |

|

GS24-07 |

13.2 |

168.0 |

154.8 |

0.23 |

0.313 |

0.008 |

1.19 |

0.533 |

0.53% |

0.709 |

|

GS24-08 |

105.0 |

174.0 |

69.0 |

0.19 |

0.217 |

0.006 |

0.56 |

0.433 |

0.40% |

0.533 |

|

and |

186.0 |

302.0 |

116.0 |

0.15 |

0.134 |

0.006 |

0.19 |

0.385 |

0.29% |

0.391 |

|

GS24-09 |

151.0 |

274.0 |

123.0 |

0.21 |

0.165 |

0.010 |

0.21 |

0.808 |

0.41% |

0.542 |

|

GS24-10 |

46.0 |

256.0 |

210.0 |

0.23 |

0.285 |

0.007 |

1.19 |

0.447 |

0.50% |

0.671 |

|

including |

110.0 |

178.0 |

68.0 |

0.37 |

0.580 |

0.005 |

1.83 |

0.260 |

0.86% |

1.142 |

|

GS24-11 |

185.0 |

210.0 |

25.0 |

0.12 |

0.016 |

0.003 |

0.53 |

0.298 |

0.17% |

0.25 |

|

GS24-12 |

301.0 |

320.4 |

19.4 |

0.13 |

0.095 |

0.005 |

0.74 |

0.353 |

0.23% |

0.33 |

|

GS24-13 |

254.0 |

305.0 |

51.0 |

0.17 |

0.181 |

0.04 |

0.004 |

0.172 |

0.32% |

0.46 |

|

GS24-15 |

24.0 |

44.0 |

20.0 |

0.37 |

0.194 |

0.057 |

0.33 |

3.539 |

0.87% |

1.26 |

|

and |

66.0 |

104.0 |

38.0 |

0.18 |

0.105 |

0.006 |

0.66 |

0.460 |

0.29% |

0.42 |

|

and |

171.0 |

225.0 |

54.0 |

0.22 |

0.155 |

0.013 |

0.54 |

1.062 |

0.42% |

0.60 |

|

GS24-16 |

Pending |

|

|

|

|

|

|

|

|

|

Copper and gold equivalent calculations based on the following metal prices which were used in the Company’s 2024 Integrated Resource Estimate for

Cu =

Note on equivalent calculation:

Copper equivalent is determined by calculating total contained metal value per tonne, dividing by the copper price, and then dividing the resultant number of pounds of copper by 2204.6. Gold equivalent is determined by calculating total contained metal value/tonne, dividing by the gold price, and then multiplying the resultant number of troy ounces of gold by 31.103. Analyzed metal equivalent calculations are reported for illustrative purposes only and assume 100% recoveries as metallurgical testing has not yet been completed on material from the West Goodspeed target.

Table 3 shows the collar data for the holes drilled at West Goodspeed during 2023 and 2024.

Table 3: West Goodspeed 2023 and 2024 Drill Hole Collar Locations

|

Hole ID |

Length

|

UTM

|

UTM

|

UTM

|

Azimuth |

Dip |

|

GS23-04 |

384 |

573657 |

5617478 |

341 |

225 |

-80 |

|

GS23-05 |

294 |

573387 |

5617444 |

312 |

90 |

-55 |

|

GS24-06 |

531 |

573674 |

5617304 |

338 |

60 |

-85 |

|

GS24-07 |

366 |

573673 |

5617302 |

338 |

270 |

-60 |

|

GS24-08 |

387 |

573903 |

5617369 |

379 |

170 |

-80 |

|

GS24-09 |

471 |

573903 |

5617369 |

379 |

125 |

-60 |

|

GS24-10 |

396 |

573462 |

5617614 |

324 |

250 |

-45 |

|

GS24-11 |

378 |

573661 |

5617798 |

341 |

180 |

-60 |

|

GS24-12 |

549 |

573889 |

5617686 |

413 |

180 |

-65 |

|

GS24-13 |

495 |

574491 |

5617411 |

471 |

220 |

-55 |

|

GS24-14 |

324 |

573005 |

5616664 |

303 |

85 |

-60 |

|

GS24-15 |

318 |

573280 |

5617720 |

296 |

230 |

-70 |

|

GS24-16 |

390 |

573279 |

5617725 |

295 |

300 |

-45 |

Field mapping during 2024 has confirmed the existence of late fault sets parallel to the major mineralization bounding faults as shown by the red dashed lines in Figure 1, which also shows the location of the drill collars for completed drill holes in a birds-eye view looking northeast towards West Goodspeed. Holes GS24-11 and GS24-12 were drilled south, oblique to the interpreted post-mineral faults in an effort to test mineralization at depth and confirm the orientation and continuity of the late mineralization off-setting faults. GS24-13 was drilled southwest, perpendicular to the interpreted fault to further test the orientation of this late structure, as well as the down-dip and along-strike continuity of the mineralization. Holes GS24-11 through GS24-13 were successful in testing for dislocated, re-mobilized mineralization associated with the post mineral faults, similar to the interpreted origins of the

GS24-15 was drilled southwest and intersected three distinct mineralized zones, all bound by faults, and showed intensely telescoped alteration domains, highlighting the potential for a coalesced mineralized system.

GS24-16 was added to the program following receipt of previous assays and was drilled southwest towards the Red Dog deposit to test the continuity of mineralization in that direction. The bottom of this hole is only 200 metres from historic holes on the margin of the proposed Red Dog pit. It intercepted intense quartz-magnetite, quartz-amphibole-biotite and quartz-chlorite-magnetite vein stockworks and parallel vein arrays hosting chalcopyrite-bornite mineralization. This hole shows that additional drilling is warranted in the untested area between the Red Rog and West Goodspeed deposits. Assays for GS24-16 are anticipated in late 2024.

Figure 2 shows the drilling at West Goodspeed in a plan view, as well as additional targets in the Red Dog /

The two post mineralization faults shown in Figures 1, 2 and 3 appear to control the present location of porphyry style copper-gold mineralization and associated alteration. Alteration manifests as a retrograde potassic assemblage, consisting of chlorite-magnetite (retrograded from biotite-magnetite) which is often overprinted by quartz-sericite-pyrite alteration, as well as porphyry related sheeted magnetite or stockwork quartz magnetite and quartz-sulphide veining as shown in Figures 5 and 6. The intensity of this porphyry related veining and copper mineralization appears to increase to the northwest as seen in GS24-10 and GS24-15. The alteration becomes dominated by quartz-sericite-pyrite moving outboard from the most densely veined core, displayed as late chalcopyrite-pyrite veins with sericite halos. Marginal intrusion-related breccias are common adjacent to, or fault bounding, variably mineralized hornblende-feldspar-quartz porphyries. The marginal breccias host mineralization in the form of late pyrite-chalcopyrite veinlets as well as magnetite-chalcopyrite blebs as shown in Figure 4. Locally, thin siliceous hydrothermal breccias, also associated with mineralized intrusions, host increased gold tenors, as seen in Figure 7.

Additional drilling was completed at West Goodspeed to step out and define mineralization further to the northwest. GS24-16 was drilled northwest along strike from the GS24-15 pad to test the possible connectivity of West Goodspeed mineralization into the Red Dog area.

Figure 3 shows the Company’s working 3D model of the West Goodspeed prospect, looking down the dip between the interpreted bounding faults with the calculated copper equivalent assays using the same basis as the highlighted intervals.

Encouraging alteration, mineralization and vein textures has provided the Northisle exploration team with several vectors towards the hypogene altered core of the mineralized Red Dog/West Goodspeed porphyry system as follows:

- Mineralization at West Goodspeed exhibits multiple generations of Cu and Au +/- Ag/Re/Mo mineralization.

- Marginal magmatic hydrothermal breccias as shown in Figure 4 host multiple phases of porphyry clasts, as well as refractory quartz-chalcopyrite-pyrite vein fragments, with abundant quartz-magnetite.

- Figure 5 shows multiple phases of overprinting quartz stockwork veining.

- Inboard from magmatic breccias, vein related mineralization at West Goodspeed occurs as early banded quartz-magnetite +/- chalcopyrite veins, early quartz-chalcopyrite centerline veins (as shown in figure 6), and late magnetite-chalcopyrite +/- chlorite (after biotite) veinlets.

- Locally an intense late quartz-sericite-pyrite overprint supplies another phase of copper mineralization. The alteration and mineralization relationships are consistent with those observed at Island Copper.

There appears to be a correlation between increased veining and increased copper grades, which is consistent with most other porphyry Cu-Au deposits. This relationship suggests conventional vein density and alteration vectoring can be used to target at West Goodspeed. Copper equivalent grades appear to correlate best with increased stockwork vein abundance and increased iron-metasomatism as seen in GS24-10.

GS24-15 intersected three zones of mineralization, bound by two post mineral faults as shown in figure 3. Mineralization at the top of the hole occurred in a texturally obliterated feldspar porphyry with an intense copper additive quartz-sericite-pyrite overprint. Mineralization at depth was hosted in a chlorite-magnetite altered porphyry with local undulous quartz-sulphide veins. This transitioned to patchy, but intense albite alteration (Figure 8) variably over printed by texturally destructive sericite-illite alteration. The juxtaposition of deep level and high level alteration is indicative of potentially intense telescoping at West Goodspeed.

Holes GS24-11, GS24-12 and GS24-13 tested the far-field down-dip extents of the two bounding faults. In all instances, truncated intervals of hornblende-feldspar-quartz porphyry with associated marginal magmatic-hydrothermal breccias occur at depth which hosted strong copper mineralization. GS24-13 also intersected thin intervals of intense silicious hydrothermal brecciation overprinted by illite adjacent to thin hornblende-feldspar-quartz porphyries which hosted an increase in copper and gold grade, as shown in Figure 7.

Mineralized zones in all three holes were bounded by brittle-ductile faults with abrupt alteration changes across their boundaries. The faulted nature of the contacts, and the similarities between the

The next phase of drilling at West Goodspeed is being planned for 2025, with the objective of defining the extents of mineralization in the area to the north of West Goodspeed and east of the Red Dog deposit as well as along strike southeast of West Goodspeed, utilizing the above-described vectors. Additional drilling will be carried out exploring the potential for further mineralization in the hanging wall and foot wall of the two faults structurally bounding the

Note the similarities to West Goodspeed marginal breccias, including clast boundaries, speciation, as well as similar alteration (quartz magnetite alteration overprinted by quartz-sericite-pyrite). The marginal breccias at the Island Copper deposit often occur adjacent to the high -grade mineralized shell at depth, and decrease in volume with depth, providing a potential vector for mineralization at West Goodspeed following the Island Copper model. Note also the refractory veins hosted in the marginal breccia at Island Copper.

Upcoming Catalysts

The Company continues to advance the

- COMPLETED - Geophysics results from Northwest Expo and West Goodspeed

- COMPLETED - Northwest Expo metallurgical testing and initial resource estimate

- COMPLETED - Final 2023 Pemberton Hills Drill Results

- COMPLETED - Commencement of 2024 drilling program

- COMPLETED - Preliminary Project Trade-offs

- COMPLETED - Commencement of advanced economic and technical studies

- COMPLETED - Initial drill results from West Goodspeed

- COMPLETED - Integrated North Island Project Mineral Resource Estimate Update

- Late Q4 2024 - Additional West Goodspeed Exploration Results

- Q4 2024 – Northwest Expo Exploration Results

- Late 2024 / Early 2025 – Final 2024 West Goodspeed Exploration Results

-

Early Q1 2025 -

North Island Project 2024 PEA - Ongoing -Continued positive engagement with indigenous rightsholders and local stakeholders

Upcoming Investor Events

The Company will continue to be active in investor outreach. Northisle will be attending several external investor events including the following events during Q4 2024 / Q1 2025:

-

November 20 – 21:Swiss Mining Institute ,Zurich, Switzerland -

January 14 – 16, 2025: TD AnnualGlobal Mining Conference ,Toronto, ON ,Canada -

January 19 – 20, 2025:Vancouver Resource Investment Conference ,Vancouver, BC ,Canada -

January 20 – 23, 2025: AME Roundup,Vancouver, BC ,Canada -

February 3, 2025 :Canadian Critical Minerals Opportunities Forum ,New York ,United States -

March 2 – 5, 2025:Prospectors & Developers Association of Canada (PDAC),Toronto, ON ,Canada

Additional Technical Details

Logging, Sampling and Assaying Procedures and QA/QC

The diamond drill core logging and sampling program was carried out under a rigorous quality assurance / quality control (QA/QC) program. Drill intersections in this release are typically HQ to 100 m and NQ thereafter to the end of holes. After drilling, core was logged for geology, structure, and geotechnical characteristics utilizing Geospark© core logging software, then marked for sampling and photographed on site. The cores for analyses were marked for sampling based on geological intervals with individual samples 3 m or less in length. Drill core was cut lengthwise in half with a core saw. Half-core was sent for assays reported in this news release. Prior to cutting core for assay bulk density was also determined on site by taking 15 to 20 centimetres (cm) lengths of whole core of each lithology at 10 m intervals. The ends of these were then cut at right angle to the core axis, retaining all pieces to be returned to the core box for later sample cutting and analysis. The diameter of each core sampled for bulk density was measured at each end with digital calipers to 3 decimal places and recorded. The length of the core was measured on four sides at 90 degrees to each other, to 2 decimal places and recorded. The software averaged the lengths and diameters. The mass of the dry core was measured twice on an Ohaus© balance to 2 decimal places. If no discrepancy occurred the measurement was recorded. If there was a discrepancy the measuring was repeated until no discrepancy between 2 measurements occurred. The density was calculated using the formula Bulk Density = π times r² times h (where r is radius of core and h is length of core). Certified standard masses are used to calibrate the scale balance used for bulk density determinations. The balance in the core logging area was levelled on a large concrete block to avoid vibration, was leveled, and surrounded by a wooden partition to avoid wind affecting the balance. The measurements were recorded in Geospark© logging software and Bulk Density calculated to 2 decimal places.

A total of 5% assay standards or blanks and 5% core duplicates are included in the sample stream as a quality control measure and are reviewed after analyses are received. Standards were obtained from WCM Minerals,

Pulps and rejects of holes with significant assay intervals are stored at Western Mineral Storage. The remaining split core is indexed and stored at Northisle logging and office facility in

Drill Results in this news release are length weighted averages.

Qualified Persons and Data Verification

About Northisle

For more information on Northisle please visit the Company’s website at www.northisle.ca.

Cautionary Note Regarding Adjacent and Historical Property Disclosure

This news release contains information regarding adjacent and historical properties and deposits. Investors are cautioned that adjacent mineral deposits or systems, or past performance of historical mines, do not necessarily indicate and certainly do not prove the existence, nature or extent of mineral deposits on the

Cautionary Statements regarding Forward-Looking Information

Certain information in this news release constitutes forward-looking statements under applicable securities law. Any statements that are contained in this news release that are not statements of historical fact may be deemed to be forward-looking statements. Forward-looking statements are often identified by terms such as “may”, “should”, “anticipate”, “expect”, “intend” and similar expressions. Forward-looking statements in this news release include, but are not limited to, statements relating to the MRE; plans and expectations regarding the 2024 exploration program; plans and expectations regarding future project development; timing of key catalysts; planned activities, including further drilling, at the

Readers are further cautioned not to place undue reliance on forward-looking statements as there can be no assurance that the plans, intentions, or expectations upon which they are placed will occur. Such information, although considered reasonable by management at the time of preparation, may prove to be incorrect and actual results may differ materially from those anticipated. Forward-looking statements contained in this news release are expressly qualified by this cautionary statement.

The forward-looking statements contained in this news release represent the expectations of management of Northisle as of the date of this news release, and, accordingly, are subject to change after such date. Northisle does not undertake any obligation to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as expressly required by applicable securities law.

Neither the

View source version on businesswire.com: https://www.businesswire.com/news/home/20241028558695/en/

On behalf of

Chief Financial Officer

Tel: (604) 335-3590

Email: info@northisle.ca

www.northisle.ca

Source: